What is Die Casting Molds and How Do They Work?

Die Casting Molds play a crucial role in the manufacturing process. These molds allow for the precise shaping of molten metal into various products. Experts in the field stress the importance of quality in these molds. John Smith, a respected authority in die casting, once stated, “High-quality molds lead to better product outcomes.”

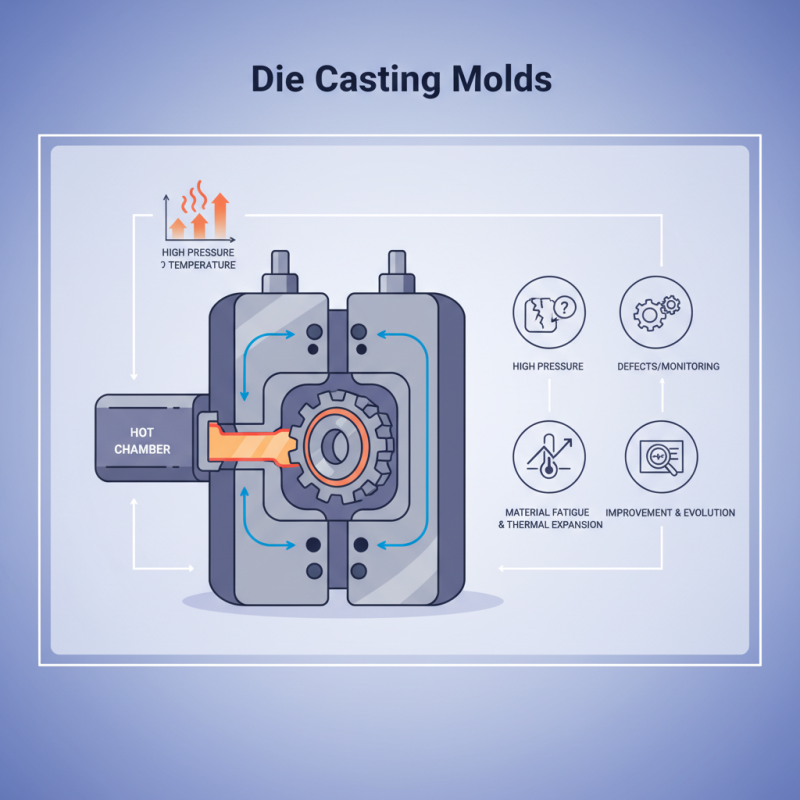

Understanding the mechanics behind die casting molds is essential. The molds are designed to withstand high pressure and temperature. The molten metal is injected into the mold cavity, where it cools and solidifies. This method ensures detailed replicas of the original design. However, it's not always perfect. Some molds can suffer from defects, requiring careful monitoring.

The industry is evolving, though challenges remain. Manufacturers must consider factors like material fatigue and thermal expansion. These issues complicate the production process. Reflecting on these problems highlights areas for improvement within the die casting sector. Understanding die casting molds is vital for anyone looking to excel in manufacturing.

What is Die Casting Molds?

Die casting molds are essential tools in the manufacturing process. They allow for the production of metal parts with high precision. Typically made from steel or aluminum, these molds can withstand high temperatures. The creation of the mold involves a complex process, often requiring intense planning and design work.

In die casting, liquid metal is injected into the mold under high pressure. This process is quick and efficient, leading to fast production times. However, there are challenges. Mold wear can sometimes lead to defects in parts. Even minor imperfections can impact functionality. Regular maintenance is crucial to ensure mold longevity and part quality.

Designing die casting molds requires expertise and experience. Mistakes during the design phase can lead to significant issues during production. It's important to consider factors like cooling rates and thermal expansion. These can affect the overall performance of the mold. Continuous improvement is vital in this field, as even small changes can yield better results.

The Components of Die Casting Molds Explained

Die casting molds are crucial in manufacturing. They are designed to shape molten metal into specific forms. The molds consist of two main components: the die and the ejector. The die is where the molten metal is poured. It creates the part's exterior shape. The ejector helps remove the finished part after cooling.

A typical die casting mold is made from steel or iron. This ensures durability. High pressure is used during the casting process, sometimes exceeding 1,500 bars. This pressure forces the metal into every detail of the mold. According to industry reports, die casting achieves tolerances of ±0.1 mm, which is impressive for mass production.

Cooling channels are another vital element. These channels help the metal cool evenly. They reduce the risk of defects. However, designing effective cooling channels is often a challenge. Engineers frequently experiment with different layouts. Each adjustment aims to optimize cooling rates. Sometimes, these variations can lead to unexpected results, requiring further analysis and redesign.

Die Casting Mold Components Analysis

This bar chart represents the percentage usage of different materials in die casting molds. Steel is the dominant material, used in 45% of die casting molds, followed by aluminum at 35%, with zinc, brass, and magnesium making up the rest.

The Die Casting Process: Step-by-Step Overview

The die casting process involves several crucial steps that ensure high-quality metal parts production. Initially, molten metal is poured into a mold cavity. This is done at high pressure, allowing the metal to fill every part of the mold accurately. Data from industry reports indicates that die casting can achieve tolerances within ±0.005 inches, making it ideal for precision components.

Once the metal cools and solidifies, it is ejected from the mold. This ejection process can sometimes lead to defects. A common issue is uneven metal distribution, which may weaken the final product. According to a recent study, approximately 5% of die-cast parts are rejected due to quality concerns. Regular monitoring of mold temperature and pressure can help mitigate these issues.

After ejection, finishing processes are often necessary. These may include trimming excess material and surface treatments. It’s not uncommon for minor imperfections to arise, prompting further refinement. In fact, the finishing stage can account for up to 30% of the total production time. Optimizing these steps is essential to maintain efficiency in die casting operations while striving for the highest quality.

Types of Die Casting Molds and Their Applications

Die casting molds are essential in manufacturing. They allow for the precise shaping of metal. This process uses molten metal, poured into molds to create detailed parts. Different types of die casting molds exist, each tailored for specific applications.

One common type is the cold chamber mold. It is suited for high melting point metals like aluminum and copper. This mold operates at room temperature, ensuring a cleaner surface finish. Another type is the hot chamber mold. This version works well with low melting point metals, like zinc. Its fast operation can boost productivity significantly.

However, choosing the right mold can be challenging. Each type has pros and cons. Cold chamber molds take time to cool, while hot chamber molds risk contamination. Understanding these trade-offs is crucial. The right mold choice can lead to better efficiency and product quality. Yet, it may require experimentation and adjustments for optimal performance.

Common Materials Used in Die Casting Molds

Die casting molds play a vital role in manufacturing processes. They allow for precision shaping of various materials. Common materials used in die casting molds include steel, aluminum, and copper alloys. Each of these materials brings unique benefits and challenges to the production process.

Steel molds are the most widely used, accounting for about 70% of the market. They offer durability and strength, which is essential for high-volume production. However, they are also more expensive and can take longer to manufacture. Aluminum molds, making up roughly 20% of the market, are lighter and easier to machine. But they have a shorter lifespan compared to steel molds. Copper alloys, while less common, are known for their excellent thermal conductivity. This allows for quicker cooling, which can enhance productivity. But they can be costly.

The choice of material can significantly impact production efficiency. Many manufacturers often face challenges in selecting the ideal material. This decision often weighs heavily on cost versus performance. Reports indicate that over 30% of companies experience issues related to mold wear and deformation. This highlights the importance of understanding material properties. Proper knowledge can lead to improved outcomes in die casting processes.

What is Die Casting Molds and How Do They Work? - Common Materials Used in Die Casting Molds

| Material | Properties | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Aluminum | Lightweight, good corrosion resistance, high thermal and electrical conductivity | Automotive parts, consumer electronics, aerospace components | Low density, easy to machine, good strength-to-weight ratio | Lower melting point, not suitable for high-temperature applications |

| Zinc | High strength, excellent corrosion resistance, good surface finish | Electrical appliances, plumbing fittings, automotive components | Cost-effective, easy to cast complex shapes, good for high-volume production | Heavier than aluminum, can be brittle at low temperatures |

| Magnesium | Lowest density among metals, good machinability, great strength | Aerospace parts, automotive components, electronic housings | Excellent strength-to-weight ratio, good damping properties | Highly flammable when in powder form, more expensive |

| Copper | Excellent electrical conductivity, good thermal conductivity, corrosion resistant | Electrical connectors, heat sinks, high-end automotive components | Great electrical properties, good thermal management | Expensive, difficult to cast due to high melting point |