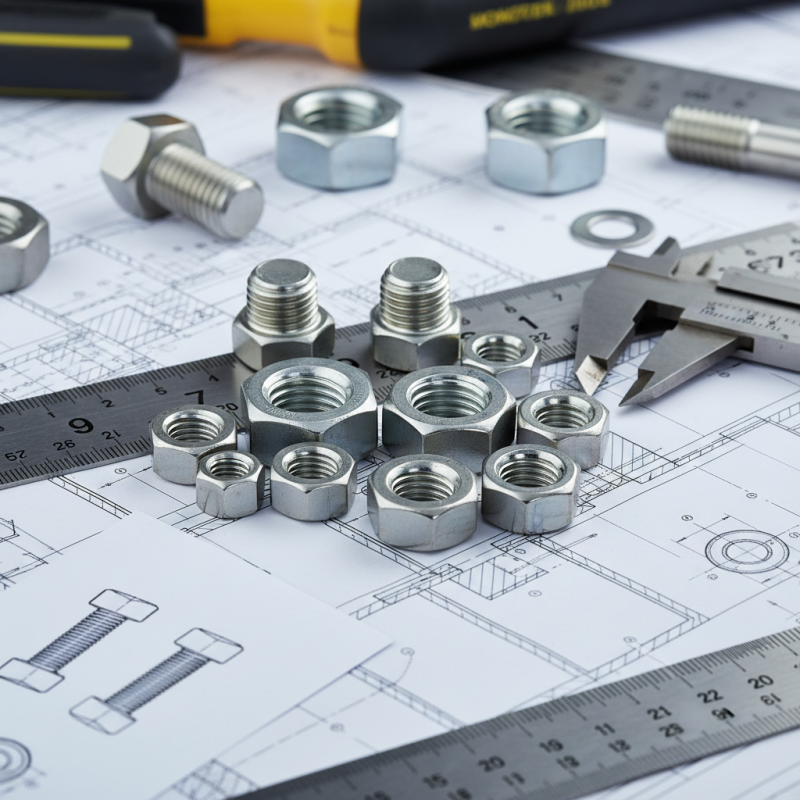

How to Choose the Right Stainless Hex Nuts for Your Project?

Choosing the right Stainless Hex Nuts is crucial for the success of your project. The global market for stainless steel fasteners is projected to grow substantially. According to industry reports, it is expected to reach $20 billion by 2026. Understanding the specifications of Stainless Hex Nuts is vital. The right selection ensures durability and strength.

In construction and manufacturing, the importance of high-quality fasteners cannot be overlooked. For instance, using inferior stainless hex nuts can lead to project failures or safety hazards. Studies show that more than 30% of mechanical failures are linked to the use of inadequate fasteners. Such statistics highlight the need for careful selection.

Moreover, the variety of materials and grades available can be overwhelming. Choosing the wrong type may cause corrosion or premature wear. It's also necessary to reflect on the project requirements and environmental conditions. Quality should be a priority, but cost cannot be ignored. Making the right choice requires a balance between price and performance.

Identifying the Requirements of Your Project

When selecting stainless hex nuts for your project, understanding your requirements is crucial. Each project varies in its needs. Consider the environment where these nuts will be used. Will they face moisture or chemicals? This affects the type of stainless steel you should choose.

Tips: If you are in a coastal area, opt for marine-grade stainless steel. It resists corrosion better. Think about the load and stress the nuts will endure. High-stress applications need heavier, stronger nuts. The size also matters. Measure accurately to prevent issues later.

Consider the threading type as well. Coarse threads are suitable for quick assembly. Fine threads offer better strength and load distribution. Reflect on your assembly process too. Will you need to take them apart frequently? This might influence your choice. Don’t rush this decision. It's easy to overlook details, but they can make a significant difference in your project's outcome.

Understanding Different Grades of Stainless Steel

When selecting stainless hex nuts, understanding the different grades of stainless steel is crucial. Stainless steel grades are classified based on their composition and properties. The most common grades include 304, 316, and 410. Each grade has specific characteristics that make it suitable for different applications. For instance, 304 stainless steel is known for its good corrosion resistance and is widely used in kitchen and food applications. Meanwhile, 316 stainless steel offers superior corrosion resistance, particularly in marine environments.

According to a report by the International Stainless Steel Forum, approximately 60% of stainless steel production consists of 304 and 316 grades. This indicates their dominance in various industries. 410 stainless steel, although less common, is known for its high strength and resistance to wear. It is often used in applications like fasteners and cutting tools. However, the lower corrosion resistance of 410 means it may not be the best choice for all environments.

Choosing the correct grade is essential for project success. Some projects may require specific properties like heat resistance or enhanced strength. Yet, many engineers overlook this critical aspect and make assumptions. This could lead to premature failure or unexpected maintenance costs down the line. When in doubt, consult material specifications and industry standards for guidance. Understanding these nuances will help ensure the right choice for your project.

How to Choose the Right Stainless Hex Nuts for Your Project? - Understanding Different Grades of Stainless Steel

| Grade | Corrosion Resistance | Strength | Applications |

|---|---|---|---|

| 304 | Good | Moderate | Food processing, architectural |

| 316 | Excellent | Moderate to High | Marine environments, medical |

| 410 | Moderate | High | Cutlery, valves |

| 2205 | Excellent | High | Oil and gas, desalination plants |

Evaluating Sizes and Measurements for Hex Nuts

When selecting the right stainless hex nuts, evaluating sizes and measurements is crucial. Standard sizes often range from 1/4 inch to 1 inch in diameter. A recent industry report highlighted that improper sizing can lead to mechanical failures in 15% of projects. Ensuring accurate measurements helps avoid these costly mistakes.

Hex nuts come in various thread pitches, including coarse and fine threads. Coarse threads tend to grip better in tougher materials, whereas fine threads offer more precision. Measurement accuracy is essential. The thread diameter should match the corresponding bolt precisely. Consider using calipers for exact readings, as they provide a more reliable measurement than a simple ruler.

Tips: Always account for the materials you'll work with. If using corrosive substances, consider using non-corrosive options. Additionally, remember that the nut should fit snugly without excessive force. If it doesn't, reevaluate your size choices. An ill-fitting nut can lead to joint slip and reduced durability, an issue that shouldn't be underestimated.

Exploring Coatings and Finishes for Durability

Choosing the right stainless hex nuts involves understanding their coatings and finishes. This is vital for enhancing durability. Common finishes include zinc plating, passivation, and hot-dip galvanization. Each coating offers different levels of corrosion resistance. For instance, zinc plating can increase lifespan significantly, providing a barrier against moisture.

Research shows that around 50% of fastener failures stem from insufficient coating protection. A study by the International Fastener Institute suggests that poor coating selection can lead to increased maintenance costs and project delays. Selecting the right coating is essential to avoid these pitfalls.

Tip: Always assess the environmental conditions your project will face. Humidity and exposure to chemicals matter. For extreme conditions, consider coatings like PTFE or nylon which provide superior protection.

When selecting finishes, think about the aesthetic as well. Functionality should not compromise appearance. Certain coatings may appear dull or uneven, which may not suit your project's visual aims. This can be difficult to rectify later. Reflect on both durability and design to make the best choice.

Assessing Cost vs. Quality in Purchasing Hex Nuts

Choosing the right stainless hex nuts involves a balance between cost and quality. Many people overlook the importance of this choice. Stainless steel is durable, but not all hex nuts are created equal. Lower-priced options may seem appealing but can lead to failures later on.

Consider the type of project you are working on. If it requires high strength or resistance to corrosion, investing in higher quality nuts is essential. Cheap hex nuts may corrode, rust, or strip threads easily. This could lead to costly replacements or even project delays.

Tip: Always check the material specifications. Look for a high grade like A2 or A4 for better corrosion resistance.

When budgeting, think long-term. The initial savings from cheaper hex nuts might not justify the potential issues. Sometimes, it's better to pay more for reliability. Quality always pays off in the end.

Tip: Buy hex nuts in bulk if possible. This can lower costs and ensure consistency in your projects.

Taking your time to assess options will help you make an informed decision. Don't rush the purchasing process, as it could impact your project's success. Every detail counts, even the smallest part.