How to Choose the Right Rubber Pump Impeller for Your Needs?

Choosing the right Rubber Pump Impeller is crucial for operational efficiency. A recent industry report from Global Market Insights indicates that the demand for rubber impellers is increasing by 5% annually. These components play a vital role in fluid dynamics and system performance.

Dr. Emily Carter, a renowned expert in pump engineering, emphasizes, "Selecting the appropriate Rubber Pump Impeller can significantly influence pump longevity." This statement highlights the importance of matching the impeller design with specific application requirements.

Many users may overlook essential factors like material compatibility and flow rate. Rubber impellers offer benefits, such as resilience and resistance to wear. However, they can sometimes degrade faster than other materials under harsh conditions. Investors should consider the operating environment and make informed choices. Selecting the right Rubber Pump Impeller is not merely about performance; it's about understanding the nuances of each application.

Understanding the Role of Rubber Pump Impellers in Fluid Dynamics

Rubber pump impellers play a crucial role in fluid dynamics. They are often chosen for their durability and ability to handle various fluids. In industries, these impellers can reduce the risk of cavitation and wear. According to a recent research report, over 30% of pump failures are attributed to impeller issues. Choosing the right material can help mitigate this.

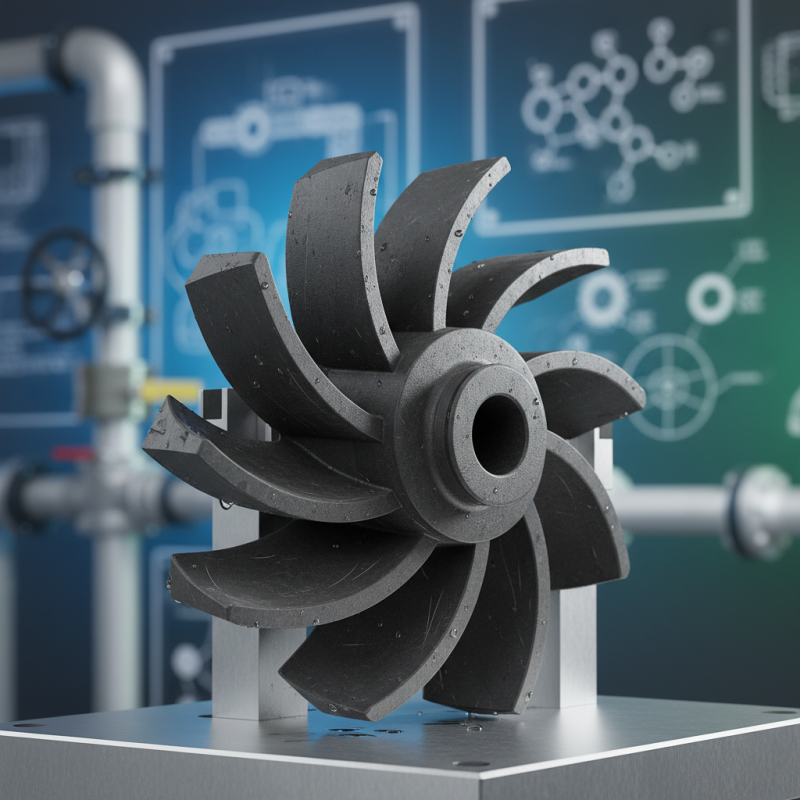

The design of a rubber impeller impacts flow efficiency. A well-designed impeller can reduce turbulence, leading to smoother operation. It is essential to consider factors such as fluid viscosity and temperature. Many experts suggest that a custom design may provide better performance. However, customizing can be expensive, and not always necessary.

Regular maintenance of rubber impellers is often overlooked. Neglect can lead to sediment buildup and decreased efficiency. In reality, almost 25% of facilities experience efficiency drops due to poor maintenance. It shows the importance of understanding both selection and upkeep. Wrong choices can lead to costly repairs and downtime, an area that often demands reflection.

Identifying Your Specific Pumping Requirements and Applications

When selecting the right rubber pump impeller, understanding your specific pumping requirements is crucial. Consider the type of fluid you'll be moving. Is it viscous or thin? Will it have solids? Each scenario affects the type of impeller you need. A high-solids mixture may require a robust, open impeller design. For clean fluids, a closed impeller could be more efficient. Recognizing these needs will guide you to make informed choices.

Next, evaluate the operating conditions. What is the temperature and pressure range? High temperatures can degrade rubber compounds. So, you might need a specialized rubber type. Similarly, consider the pump's flow rate requirements. A mismatch can lead to poor performance and wear. Choosing an impeller that meets your performance criteria is crucial. However, many overlook this aspect. It’s easy to make assumptions, but doing thorough research pays off in the long run. Always reflect on your choices and adjust as needed.

Rubber Pump Impeller Selection Criteria

Evaluating Material Options for Durability and Performance

When choosing a rubber pump impeller, material options are crucial. The two most common materials are natural rubber and synthetic rubber. Natural rubber offers excellent flexibility and resilience. It performs well in various environments, but it may not withstand extreme temperatures. Synthetic options, on the other hand, are designed for specific conditions. They often boast greater durability and strength.

Consider the specific application of the impeller. For instance, if it's exposed to harsh chemicals, a synthetic material may be a better choice. On the contrary, for standard water applications, natural rubber might suffice. Balancing flexibility with durability is essential. Each material has pros and cons. Testing them under real conditions can help you identify the best fit for your needs.

Don't forget about environmental aspects. Temperature fluctuations and chemical exposures can compromise materials over time. Proper maintenance can mitigate wear, but choosing the right material upfront is more effective. Reflect on past choices. Were they durable enough? Did they meet performance expectations? Identifying these factors will guide you in making a more informed decision in the future.

Determining Impeller Design and Size for Optimal Efficiency

Choosing the right rubber pump impeller involves understanding impeller design and size. The design significantly affects efficiency. Different designs like open, closed, or semi-closed have unique performance characteristics. An open impeller is easier to clean and handle solids, but it may have lower efficiency. A closed impeller, on the other hand, provides better head and efficiency but can clog.

Size also plays a crucial role. An undersized impeller might not move enough fluid. This can lead to increased wear and tear. Conversely, an oversized impeller can cause cavitation, which damages the pump. You must calculate the flow rate and system pressure to ensure the right size.

Also, the operating environment matters. Different materials withstand specific chemicals and temperatures. It’s essential to consider the fluid type you’ll handle. Sometimes, you could choose a suboptimal design or size, just because it seemed convenient. Understand the specific needs of your system instead. This reflection can save time and costs in the long run.

Maintenance and Replacement Considerations for Rubber Pump Impellers

Maintaining rubber pump impellers is crucial for optimal performance. Regular inspections help identify wear and tear. Look for cracks or abrasions. These issues can lead to inefficiencies. Addressing them early can save time and costs. Remember, ignoring minor damage may escalate problems.

Replacement of the impeller should not be overlooked. Rubber components degrade over time, especially in harsh environments. How often should you replace it? It depends on usage and conditions. Frequent use in abrasive materials will wear it out faster. Consider keeping a spare on hand, just in case.

Don't forget the importance of proper installation. Misalignment can cause early failure. Ensure all connections are tight. Double-check the specifications before installation. Mistakes can happen, and they often lead to costly repairs. Focus on maintaining a routine that prioritizes timely checks and replacements. Keeping a record of maintenance activities can help track performance over time.