2026 Best Stainless Steel Woven Wire Mesh Options for You?

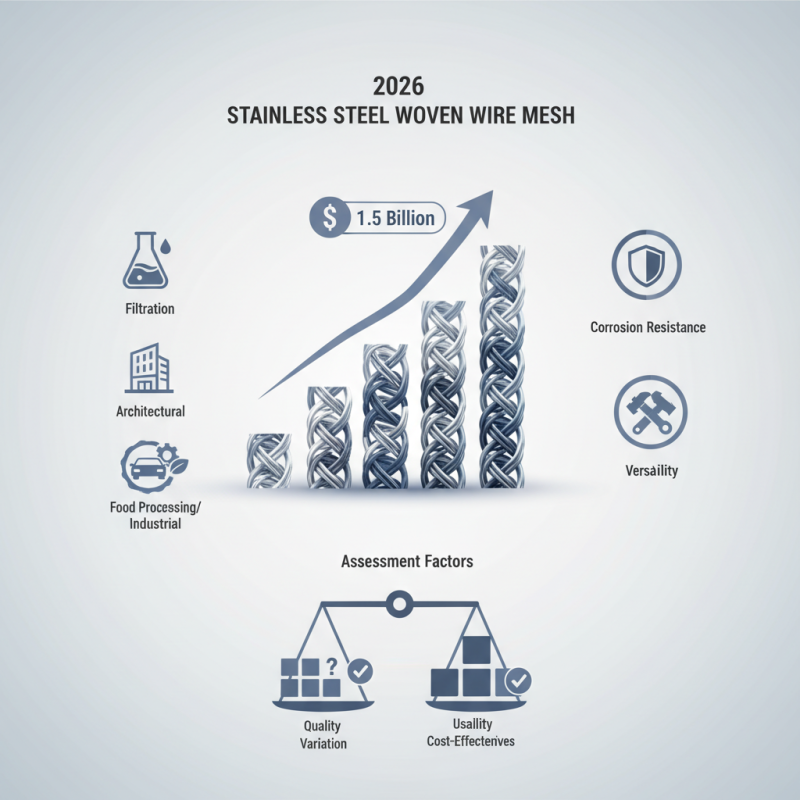

In recent years, the demand for stainless steel woven wire mesh has surged significantly. According to industry reports, the global market for stainless steel mesh is projected to reach $1.5 billion by 2026. This growth is driven by diverse applications, from filtration to architectural uses. The properties of stainless steel, including corrosion resistance and durability, make it an ideal choice for various industries.

The versatility of stainless steel woven wire mesh is impressive. It is used in construction, automotive, and food processing sectors. However, with this versatility comes some challenges. Not all woven wire meshes are created equal, and quality can vary significantly among manufacturers. It is essential to assess different options carefully to ensure the right choice aligns with specific needs.

As we explore the best options for stainless steel woven wire mesh in 2026, several factors warrant consideration. It is vital to examine specifications, usability, and cost-effectiveness. While many products offer excellent performance, some may fall short in crucial areas. Addressing these imperfections will help buyers make informed decisions in a crowded market.

2026 Overview of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh has gained popularity across various industries. Its strength, durability, and resistance to corrosion make it an ideal choice. According to industry reports, the demand for stainless steel mesh is projected to grow by 5% annually. This growth reflects a shift towards sustainable materials and high-performance products.

Applications of stainless steel mesh are diverse. It is used in filtration, architectural designs, and safety barriers. The mesh can effectively filter out particles, thanks to its varying mesh sizes. Many industries prefer this due to its longevity and low maintenance. In architecture, it provides both aesthetic appeal and practical functions.

Tips: When choosing woven wire mesh, consider the specific requirements of your project. Evaluate the mesh size, tensile strength, and corrosion resistance. A small oversight here can lead to larger issues during implementation. Remember, quality matters. Even though stainless steel is sturdy, not all options provide the same level of performance. Research is essential.

As you explore your options, reflect on the supplier's reputation. Quality assurance can vary significantly among manufacturers. Some may cut corners, impacting the material’s integrity. Ensure that you are making a well-informed choice for optimal results.

Key Factors to Consider When Choosing Woven Wire Mesh

When selecting woven wire mesh, several key factors come into play. Start with the mesh opening size. This determines what can pass through. A smaller opening blocks larger objects, while a larger one allows air and light. Think about your specific needs.

Material choice is also crucial. Stainless steel is common because of its durability and corrosion resistance. It works well in various environments. However, understand that different stainless steel grades offer different properties. Some might be more suitable than others.

Tips: Always evaluate the environment where the mesh will be used. Will it face extreme temperatures or corrosion? This can affect longevity. Also, consider the mesh's weaving pattern. It influences strength and flexibility.

Lastly, don't overlook the mesh's finish. A smooth finish can prevent snagging, while a rough finish offers better grip. Reflect on how these different factors align with your project goals. Choosing the right woven wire mesh requires careful consideration of details. It's not just about aesthetics; it's about functionality too.

Top Applications for Stainless Steel Woven Wire Mesh in 2026

In 2026, stainless steel woven wire mesh will find applications across various industries. Its durability and resistance to corrosion make it a favorite in construction. According to recent industry reports, the construction sector is forecasted to grow by 5.4% annually, increasing demand for quality wire mesh. This material plays a critical role in facades, safety barriers, and architectural designs.

The food and beverage industry also heavily relies on this versatile mesh. Reports indicate that over 40% of stainless steel mesh is used in food processing, owing to its hygiene and easy maintenance. The mesh prevents contamination while allowing air circulation. However, the high initial costs can be a barrier for small-scale producers. They often overlook more affordable alternatives, which can lead to challenges in compliance and safety.

Additionally, the aerospace industry is emerging as a significant user of stainless steel woven wire mesh. It provides structural support and filtration, optimizing performance. However, not all companies can meet the stringent quality standards required in aerospace applications. This gap raises questions about reliability and product consistency. Some firms might rush production, compromising overall performance and safety.

Comparison of Different Types of Stainless Steel Woven Wire Mesh

When exploring stainless steel woven wire mesh options, it's essential to understand the different types available. This mesh can vary in weave patterns. Common types include plain weave, twill weave, and Dutch weave. Each style offers unique characteristics, which can greatly impact its application.

Plain weave is the most basic form. It's strong but not very flexible. Twill weave, on the other hand, provides better flexibility and strength. This makes it ideal for applications requiring more durability. Dutch weave combines both tight and coarse weaving techniques, resulting in a mesh that is perfect for filtration purposes. Each type requires careful consideration of material and usage.

While selecting the right mesh, it is easy to overlook specific needs. The wire diameter, mesh size, and opening shapes can influence functionality. Users often prioritize strength but might neglect other factors like corrosion resistance. It’s crucial to balance these attributes for the desired outcome. Choosing the correct type might feel overwhelming, yet researching these differences can lead to better decisions.

2026 Best Stainless Steel Woven Wire Mesh Options Comparison

Maintenance Tips for Long-Lasting Stainless Steel Wire Mesh

When considering stainless steel woven wire mesh, maintenance is key for longevity. Regular care can enhance its lifespan significantly. Reports indicate that properly maintained mesh can last over 25 years, even in harsh environments. However, neglect can lead to wear and corrosion, affecting performance.

To maintain your stainless steel mesh, start with regular cleaning. Use mild detergents and warm water. This removes dirt and contaminants that can cause rust. Rinse with clean water. Avoid abrasive materials; they can scratch the surface. For a deeper clean, consider an acid-based cleaner every few years.

Another tip is to inspect for any signs of damage. Look for loose wires or corrosion. Early detection allows for timely repairs, saving costs in the long run. Store the mesh rolled up when not in use to prevent kinks. Even small neglect can accumulate, leading to bigger issues. Keep records of your maintenance; tracking care routines helps identify patterns for improvement. Regular attention can help ensure your stainless steel wire mesh not only lasts but performs optimally.

2026 Best Stainless Steel Woven Wire Mesh Options for You? - Maintenance Tips for Long-Lasting Stainless Steel Wire Mesh

| Mesh Type | Wire Diameter (mm) | Opening Size (mm) | Applications | Maintenance Tips |

|---|---|---|---|---|

| Plain Woven Wire Mesh | 0.5 | 2.5 | Filtration, Sifting | Regular cleaning with mild soap, avoid harsh chemicals |

| Twill Woven Wire Mesh | 0.8 | 3.0 | Industrial Filtration, Security Screens | Lubricate joints, check for rust regularly |

| Dutch Weave Wire Mesh | 0.4 | 1.5 | Gas Filtering, Liquid Filtration | Flush with water after use, avoid direct sunlight |

| Expanded Metal Mesh | 1.0 | N/A | Architectural Applications, Grills | Clean with a soft cloth, repaint if necessary |