What is a Ball Bearing and How Does it Work?

Ball Bearings are essential components in many machines we rely on daily. According to industry expert John McKenzie, “Ball bearings are vital for reducing friction and enhancing performance.” Understanding their function is key.

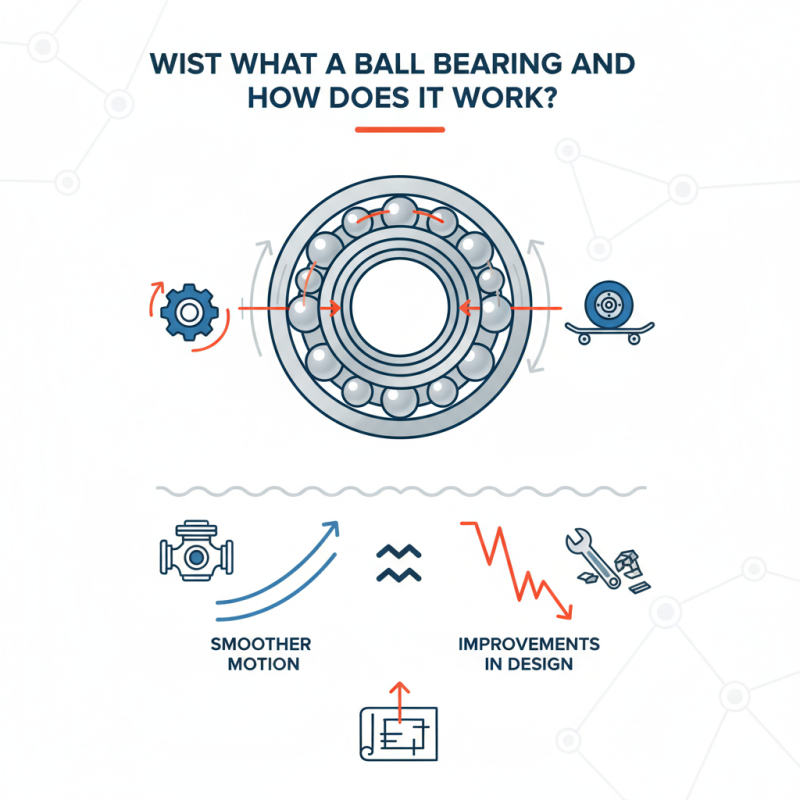

A ball bearing works by using small, spherical balls between two surfaces. These balls help minimize friction. The result is smoother motion, whether in an engine or a skateboard wheel. However, not all ball bearings are created equal. Variations in quality can lead to inconsistent performance.

In some cases, manufacturers overlook the importance of precision in their ball bearings. This oversight can lead to premature wear and increased maintenance costs. Reflecting on this aspect can drive improvements in design and production processes. The ball bearing industry is constantly evolving, making it crucial to stay informed about advancements.

What is a Ball Bearing: Definition and Key Components

A ball bearing is a crucial component in many machines. It helps reduce friction between moving parts. The design of a ball bearing includes an outer race, inner race, and ball elements. These balls are usually made of steel or ceramic. They sit in a circular formation between the inner and outer race. This setup allows them to rotate smoothly.

The key component of a ball bearing is its ability to support heavy loads while maintaining speed. Each ball must fit precisely within its designated space. If they are too loose, they can rattle and wear down quickly. If they are too tight, they may not spin at all. It’s a delicate balance that requires attention.

Over time, bearings can lose their effectiveness. Dirt and debris can gather, causing friction to increase. Regular maintenance is important to avoid premature failure. Observing the condition of the bearing is vital. Small signs of wear can lead to larger issues if ignored. In certain situations, users may overlook the bearing's role in overall machinery function. Yet, its presence is essential for reliable operation.

What is a Ball Bearing and How Does it Work?

| Component | Description | Material | Common Applications |

|---|---|---|---|

| Inner Race | The inner ring that houses the balls and rotates with the shaft. | Steel or ceramic | Electric motors, automotive systems |

| Outer Race | The stationary ring that contains the balls in a track. | Steel or plastic | Machine tools, bicycles |

| Balls | The spherical components that reduce friction between the races. | Steel, ceramic, or plastic | Fans, hard drives |

| Cage | The structure that separates the balls to prevent contact and maintain spacing. | Steel or plastic | Automobiles, conveyors |

| Lubricant | Substance that minimizes friction and wear between moving parts. | Oil or grease | All rotating machinery |

History of Ball Bearings: Evolution and Milestones in Design

The history of ball bearings is rich and intriguing. From ancient times to modern technology, ball bearings have evolved significantly. In the early 1700s, Leonardo da Vinci conceptualized the idea of ball bearings. His sketches hinted at a rotating mechanism. However, it wasn't until the 19th century that practical applications emerged. The first patented ball bearing appeared in 1794, revolutionizing machinery.

By 1869, Isaac Pitt invented a ball-bearing design that enhanced stability. This milestone improved efficiency in various machines, leading to increased industrial productivity. Reports indicate that the global ball bearing market reached approximately $28 billion in 2020. Experts project a steady growth rate of 6% annually from 2021 to 2028.

Tips: When choosing ball bearings, consider load capacity and speed ratings. Proper selection improves performance. Regular maintenance is essential. Well-maintained bearings ensure longevity.

As technology advanced, the materials used in ball bearings improved. Steel was common for decades, but newer composites have emerged. Some designs now incorporate ceramic elements. These innovations provide higher resistance to heat and corrosion. However, challenges persist with the cost and manufacturing processes of these advanced materials.

Understanding the history behind ball bearings helps appreciate their role in modern machinery. Each milestone has contributed to their current design and functionality. Reflecting on these developments reveals both achievements and areas needing further innovation.

Principle of Operation: How Ball Bearings Reduce Friction and Wear

Ball bearings play a vital role in reducing friction and wear in various machines. They work by allowing a rotating shaft to move smoothly with minimal resistance. As the balls roll between two surfaces, they create a low-friction layer, which improves efficiency. Industry studies reveal that the proper use of ball bearings can reduce friction by up to 90%. This significant reduction allows machinery to operate at higher speeds without overheating.

The principle of operation is quite fascinating. Each ball in a bearing makes contact with the inner and outer races. This contact minimizes surface area, which lowers friction. However, the alignment of the balls must be perfect. Misalignment can lead to premature wear and failure. Reports show that improper installation leads to 30% of bearing failures in industrial settings.

Moreover, materials used in ball bearings have evolved. Advanced ceramics can withstand higher loads and temperatures. Yet, they can be brittle and may shatter under stress. The challenge remains to balance durability and performance. Understanding these nuances is essential for optimizing machinery in a variety of applications.

Applications of Ball Bearings: Industries and Devices That Utilize Them

Ball bearings are everywhere, silently supporting our daily lives. They are critical components in various industries. From automotive to aerospace, their role is crucial. In manufacturing, ball bearings facilitate smooth movements in machines. They handle high-speed rotations and reduce friction. This enhances efficiency and prolongs the lifespan of equipment.

These bearings are not limited to heavy machinery. Small devices like fans, hard drives, and toys also rely on them. Without ball bearings, these gadgets would struggle to function. Friction would cause wear and tear, leading to failure. Yet, their design can be flawed. Sometimes, selecting the wrong type can lead to inefficiency. Also, improper installation may create issues later on. Regular maintenance is vital to prevent problems.

Additionally, industries like robotics and electronics benefit greatly from ball bearings. They often provide precision in movement. Yet, we often overlook their importance. They are small but mighty. Their influence on innovation can’t be understated. In many designs, engineers face the challenge of integrating them seamlessly. It’s a balancing act between size, load capacity, and durability. Each choice impacts performance.

Material Composition: Common Materials Used in Ball Bearing Manufacturing

Ball bearings are crucial components in many machines. Their efficiency relies heavily on the materials used in their manufacturing. Common materials include steel, ceramic, and plastic. Each material has unique properties affecting performance and durability.

Steel ball bearings are popular due to their strength and load capacity. High-carbon steel is often chosen for its excellent wear resistance. However, they can rust under moisture, which is a drawback. Ceramic materials, on the other hand, are lighter and resistant to corrosion. Yet, they can be more brittle than steel. Balancing these aspects can be tricky when designing for specific applications.

Plastic ball bearings offer another alternative. They are lightweight and can resist chemicals well. Yet, their load-bearing capacity is lower compared to metal options. This choice often leads to compromises in durability. Engineers must carefully consider these factors when selecting materials. Maintaining performance while minimizing costs is a lingering challenge. Each material presents opportunities but also limitations that require thoughtful evaluation.